CHP

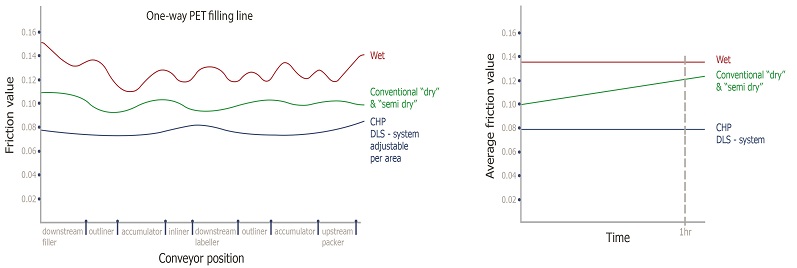

Konveyör ve PET şişe havai hat sistemlerinde "kuru kaydırıcı" uygulamasının mucididir. Son yapılan geliştirmelerle MicroDry™ Lubrication adı verilen sistemle en düşük kuru kaydırıcı kullanımı ve en düşük sürtünme katsayısı elde edilmektedir.

|

|

|

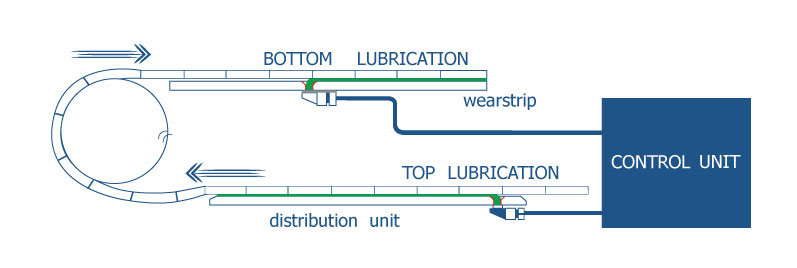

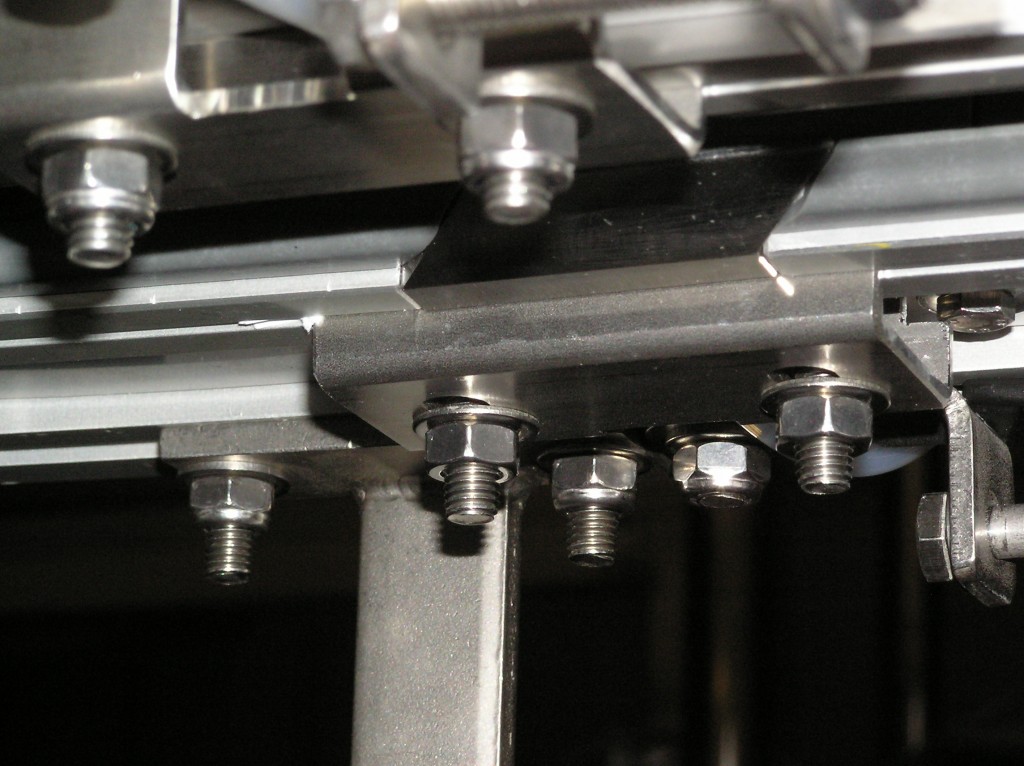

Sistem merkezi kontrol ünitesi vasıtasıyla 50 metre yarıçapa kadar olan tüm hatların yağlanmasına olanak sağlamaktadır. Kaydırıcı, her hatta ve her konveyöre kontrollü olarak verilmektedir.

|

|

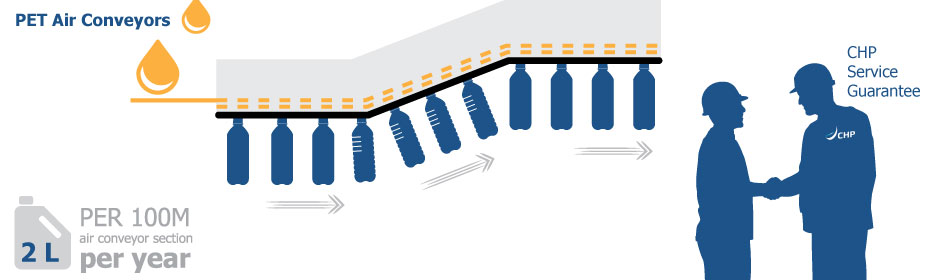

Merkezi ünite vasıtasıyla PET şişe havai hatlarının da kuru kaydırıcı vasıtasıyla yağlanması mümkündür

|

|

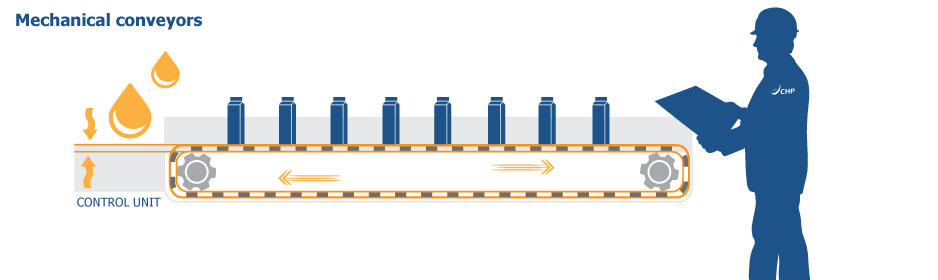

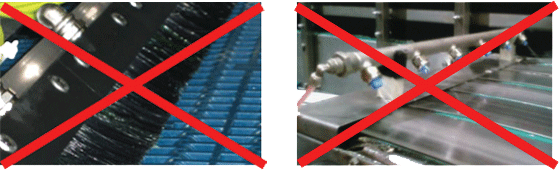

Tamamen bakımsız olup, yağlama direk olarak plastik konveyör zinciri/bandı üzerine uygulanmaktatır. Bu sebeple diğer sistemlerdeki gibi yağın ziyan olması engellenmektedir.

|

DLS-5000 ve DLAC CHP MicroDry™ lubrication ekipmanları, gıdaya uygun kuru kaydırıcı DLT-333 kuru kaydırıcı ile çalışmaktadır.

Bu yağın özelliklerini şu şekilde özetleyebiliriz :

FDA onaylı : NSF H1 sertifikalı

1 yıl raf ömrü

Oluşturduğu mikroskopik ince film, yapışkan ve suya dayanıklı

Ürün üzerine bulaşmaz

PET şişelere nüfuz etmez ve gerilme çatlaması oluşturmaz

CHP MicroDry™ ile minimum kullanım sağlar

Yukarıda bahsedilen CHP MicroDry™ sistemi ve DLT-333 kuru kaydırıcı yağ, Krones, KHS, Sidel, Tetrapak, SIG Combiblock ve Alliance Industrial tarafından onaylanmıştır.

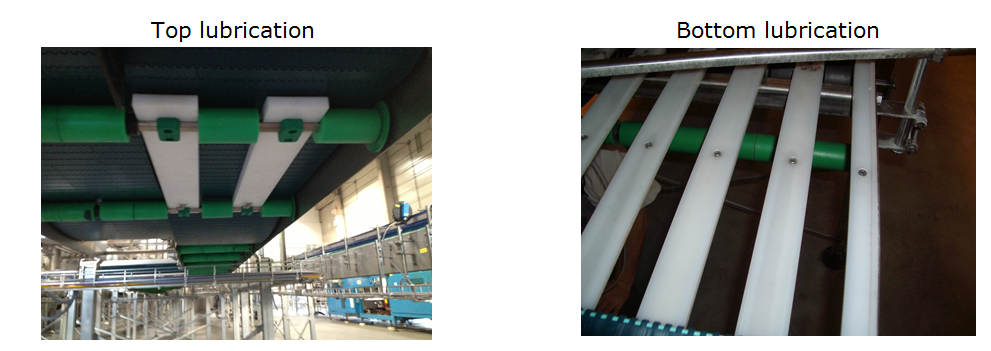

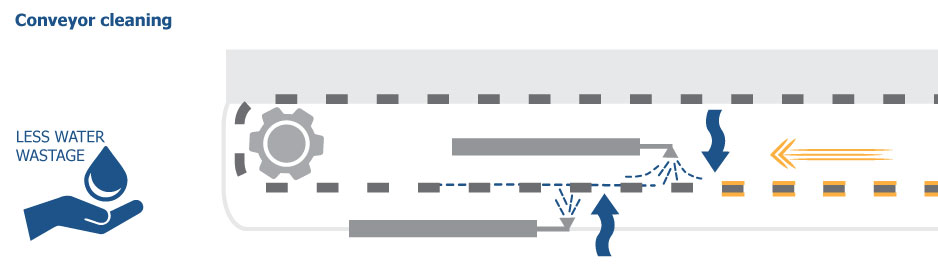

Paketleme ve şişeleme sektöründe bir ihtiyaca cevap verebilmek amacıyla yağlama ile birlikte, konveyör temizliğine de ( CIP ) çözüm getirilmiştir. Bu yeni sistemle, zincir/bant alt/üst yüzey yağlaması ve konveyör iç ve dış temizliği de kompak bir ünite ile karşılanmaktadır

|

|

|

© 2025 ELBAK Makina, Mühendislik ve

© 2025 ELBAK Makina, Mühendislik ve